Student Learning Centric Odd Semester details(2023-2024)

| Sl. No. | Subject Name | Subject Code | Faculty Name | Course Modules | Lesson plan | Notes of lessons | PPT | Laboratory Manual | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Mechanics of Materials | BME301 | Mr.Anand H R | Link | Link | Link | ||||||

| 2 | Manufacturing Process | BME302 | Mr.Vinay L | Link | Link | Link | Link | |||||

| 3 | Material Science & Engineering | BME303 | Mr.Rajashekar B Sannmani | Link | Link | Link | Link | |||||

| 4 | Basic Thermodynamics | BME304 | Mr.Hanoca P | Link | Link | Link | ||||||

| 5 | Introduction to Modelling and Design for Manufacturing | BMEL305 | Mr.Rajeev K T | Link | Link | Link | ||||||

| 6 | Smart Materials | BME306b | Mr.Pavan Kumar K K | Link | Link | Link | ||||||

| 1 | Applied Thermodynamics | BME401 | Mr.Rajeev K T | |||||||||

| 2 | Machining Science & Metrology | BME402 | Mr.Anand H R | |||||||||

| 3 | Fluid Mechanics | BME403 | Mr.Hanoca P | |||||||||

| 4 | Mechanical Measurements & Metrology | BMEL404 | Mr.Anand H R | |||||||||

| 5 | Non Traditional Machining | BME405a | Mr.Pavan Kumar K K | |||||||||

| 6 | Biology for Engineers | BBOK407 | Mr.Rajashekar B Sannmani | |||||||||

| 1 | Theory of Machines | 21ME51 | Dr.Kuldeep B | Link | Link | Link | Link | |||||

| 2 | Thermo fluids Engineering | 21ME52 | Mr.Hanoca P | Link | Link | Link | Link | |||||

| 3 | Finite Elememt Analysis | 21ME53 | Mr.Pavan Kumar K K | Link | Link | Link | ||||||

| 4 | Modern mobility and Automotive mechanics | 21ME54 | Mr.Rajeev K T | Link | Link | Link | Link | |||||

| 5 | Design Lab | 21MEL55 | Dr.Kuldeep B | Link | Link | Link | ||||||

| 6 | RM & IPR | 21ME56 | Mr.Rajashekar B Sannmani | Link | Link | Link | ||||||

| 7 | Environmental Studies | 21CIV57 | Manjunath K H | Link | Link | Link | ||||||

| 8 | Basics of Matlab | 21ME581 | Mr.Rajashekar B Sannmani | Link | Link | Link | ||||||

| 1 | Production and Operation Management | 21ME61 | Mr.Pavan Kumar K K | |||||||||

| 2 | Heat Transfer | 21ME62 | Mr.Hanoca P | |||||||||

| 3 | Machine design | 21ME63 | Mr.Anand H R | |||||||||

| 4 | Autonomous Vehicles | 21ME643 | Mr.Rajashekar B Sannmani | |||||||||

| 5 | Occupational Health and Safety | 21CV653 | Mr.Manjunath K H | |||||||||

| 6 | CNC programming & 3D printing Lab | 21MEL66 | Mr.Rajeev K T | |||||||||

| 27 | Control Engineering | 18ME71 | Dr.Kuldeep B | Link | Link | Link | Link | |||||

| 27 | Computer Aided Design and Manufacturing | 18ME72 | Mr.Vinay L | Link | Link | Link | Link | |||||

| 27 | Total Quality Management | 18ME73 | Mr.Dharanesh O H | Link | Link | Link | Link | |||||

| 27 | Mechatronics | 18ME74 | Mr.Anand H R | Link | Link | Link | Link | |||||

| 27 | Electric Vehicles | 18EE752 | Dr.Sriharsha J | |||||||||

| 27 | Computer Integrated Manufacturing Lab | 18MEL76 | Mr.Vinay L | Link | Link | Link | ||||||

| 27 | Design Lab | 18MEL77 | Dr.Kuldeep B | Link | Link | Link | ||||||

| 33 | Energy Engineering | 18ME81 | Mr.Rajeev K T | Link | Link | Link | Link | |||||

| 34 | Automobile Engineering | 18ME824 | Dr.Kuldeep B | Link | Link | Link | Link |

Student Learning Centric details(2022-2023)

| Sl. No. | Subject Name | Subject Code | Faculty Name | Course Modules | Lesson plan | Notes of lessons | PPT | Laboratory Manual | Lab Videos |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Transform Calculus, Fourior Series | 21MAT31 | Mr.Somashekar M | Link | Link | Link | |||

| 2 | Metal Casting, Welding & Joining Process | 21ME32 | Mr.Vinay L | Link | Link | Link | |||

| 3 | Material Science & Engineering | 21ME33 | Mr.Anand H R | Link | Link | Link | Link | ||

| 4 | Thermodynamics | 21ME34 | Mr.Hanoca P | Link | Link | Link | |||

| 5 | Machine Drawing and GD&T | 21MEL35 | Mr.Rajeev K T | Link | Link | Link | |||

| 6 | Complex Analysis, Probability & Linear Programming | 21ME41 | Santosh B B | ||||||

| 7 | Machining Science, Jigs & Fixtures | 21ME42 | Anand H R | Link | Link | Link | Link | ||

| 8 | Fluid Mechanics | 21ME43 | Hanoca P | Link | Link | Link | Link | ||

| 9 | Mechanics of Materials | 21ME44 | Kuldeep B | Link | Link | Link | |||

| 10 | Biology for Engineers | 21BE45 | Rajashekar B Sannmani | Link | Link | Link | |||

| 11 | Mechanical Measurements & Metrology Lab | 21ME46 | Rajashekar B Sannmani | Link | Link | Link | |||

| 12 | Management and Economics | 18ME51 | Pavan Kumar K K | Link | Link | Link | Link | ||

| 13 | Design of Machine Elements-I | 18ME52 | Anand H R | Link | Link | Link | |||

| 14 | Dynamics of Machines | 18ME53 | Kuldeep B | Link | Link | Link | Link | ||

| 15 | Turbo Machines | 18ME54 | Rajeev K T | Link | Link | Link | |||

| 16 | Fluid Power Engineering | 18ME55 | Pavan Kumar K K | Link | Link | Link | |||

| 17 | Operations Management | 18ME56 | Hanoca P | Link | Link | Link | Link | ||

| 18 | Fluid Mechanics/Machines lab | 18MEL57 | Hanoca P | Link | Link | Link | |||

| 19 | Energy Conversion Lab | 18MEL58 | Rajeev K T | Link | Link | Link | |||

| 20 | Finite Element Methods | 18ME61 | Dharanesh O H | Link | Link | Link | |||

| 21 | Design of Machine Elements II | 18ME62 | Anand H R | Link | Link | Link | |||

| 22 | Heat Transfer | 18ME63 | Rajeev K T | Link | Link | Link | Link | ||

| 23 | Non-Traditional Machining | 18ME641 | Vinay L | Link | Link | Link | Link | ||

| 24 | Occupational Health & Safety | 18CV653 | Manjunath H S | Link | Link | Link | |||

| 25 | Heat Transfer Lab | 18MEL66 | Pavan Kumar K K | Link | Link | Link | |||

| 26 | CAMA lab | 18MEL67 | Rajashekar | Link | Link | Link | |||

| 27 | Control Engineering | 18ME71 | Kuldeep B | Link | Link | Link | Link | ||

| 28 | Computer Aided Design and Manufacturing | 18ME72 | Vinay L | Link | Link | Link | Link | ||

| 29 | Total Quality Management | 18ME73 | Dharanesh O H | Link | Link | Link | Link | ||

| 30 | Mechatronics | 18ME74 | Anand H R | Link | Link | Link | |||

| 31 | Electrical Energy Conservation and Auditing | 18EE754 | Hanoca P | Link | Link | Link | Link | ||

| 32 | Computer Integrated Manufacturing Lab | 18MEL76 | Dharanesh O H, Vinay L | Link | Link | Link | |||

| 33 | Design Lab | 18MEL77 | Kuldeep B | Link | Link | Link | |||

| 34 | Energy Engineering | 18ME81 | Rajeev K T | Link | Link | Link | Link | ||

| 35 | Automobile Engineering | 18ME824 | Kuldeep B | Link | Link | Link | Link |

ACHIEVEMENTS

FACULTY ACHIEVEMENTS

Faculty Achievements

Staff Publication

| Publication in Journals |

Conferences |

|

| International | National | International |

| 13 | 1 | 30 |

Staff Recognition

- Anand H R, Assistant Professor, Department of Mechanical Engineering is awarded with Ph.D in the field of Composite Materials under the guidance of Dr. Govardhan Goud in the year 2024

- Kuldeep B, Associate Professor, Department of Mechanical Engineering is awarded with Ph.D in the field of Composite Materials under the guidance of Dr. Ravi Kumar K P and Dr. Pradeep S in the year 2021.

- Kuldeep B, Associate Professor, Department of Mechanical Engineering is awarded for “Best Teacher” in the year 2023

- Kuldeep B Associate Professor, Department of Mechanical Engineering is recognised as a research supervisor for VTU in the year 2023.

STUDENT ACHIEVEMENTS

STUDENTS ACHIEVEMENTS

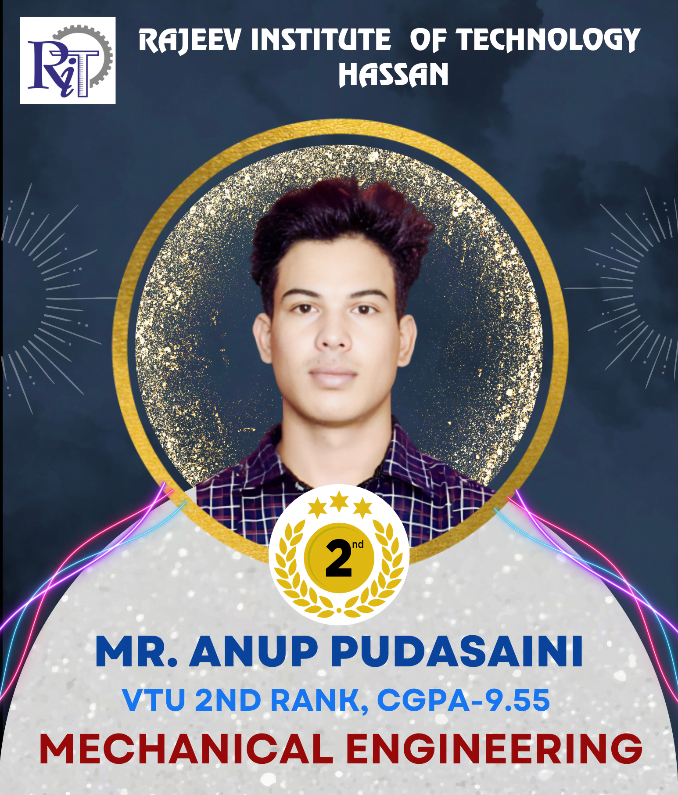

Our Student ANUP PUDASAINI of batch 2019-2023 has secured VTU

2nd Rank with a CGPA of 9.55 and also received an award of institute topper in the year 2022-23

Toppers List 2022-23

|

YEAR |

CGPA | USN |

NAME |

| 2nd | 9.17 | 4RA21ME004 | INCHARA D |

| 9.00 | 4RA21ME004 | INCHARA D | |

| 3rd | 8.12 | 4RA21ME405 | HARSHA BS |

| 8.67 | 4RA20ME005 | SATHWIK M J | |

| 4th | 9.4 | 4RA19ME004 | ANUP PUDASAINI |

| 9.5 | 4RA19ME004 | ANUP PUDASAINI |

Toppers List 2021-22

|

YEAR |

CGPA | USN |

NAME |

| 2nd | 8.54 | 4RA21ME405 | HARSHA BS |

| 8.46 | 4RA20ME005 | SATHWIK M J | |

| 3rd | 8.96 | 4RA19ME004 | ANUP PUDASAINI |

| 9.04 | 4RA19ME003 | ANIJ ANGDEMBE | |

| 4th | 9.00 | 4RA19ME402 | ARPITHA S R |

| 9.67 | 4RA19ME403 | AVINASH D D |

Toppers List 2020-21

| YEAR | CGPA | USN |

NAME |

| 2nd | 9.36 | 4RA19ME004 | ANUP PUDASAINI |

| 10 | 4RA19ME004 | ANUP PUDASAINI | |

| 3rd | 9.5 | 4RA19ME004 | ANUP PUDASAINI |

| 8.64 | 4RA19ME426 | PRADEEPA D C | |

| 4th | 9.00 | 4RA17ME023 | JOYSON DSOUZA |

| 9.65 | 4RA17ME011 | DEEKSHITH N M |

Toppers List 2019-20

| YEAR | CGPA | USN |

NAME |

| 2nd | 9 | 4RA18ME042 | SHARANYA D Y |

| 9 | 4RA18ME042 | SHARANYA D Y | |

| 3rd | 9.42 | 4RA17ME023 | JOYSON DSOUZA |

| 10.00 | 4RA17ME023 | JOYSON DSOUZA | |

| 4th | 8.83 | 4RA17ME407 | GOPISHREE C |

| 9.65 | 4RA14ME045 | KHADEER AFRIDI |

Best Projects 2022-23

| USN | Student Name | Title |

Guide |

| 4RA17ME068 | Mr. VARUN S. R | “Product Development of Weight Lifting

Exoskeleton For Soldiers” |

Mr.Dharanesh O H |

| 4RA19ME010 | Mr. KARTHIK A. S | ||

| 4RA19MEO13 | Mr. MAHADEVASWAMY M. J | ||

| 4RA19ME014 | Mr. MANOJ G. C | ||

| 4RA18ME007 | Mr. DEEKSHITH Y.R | “INTEGRATED SYSTEM FOR SUICIDE

PREVENTION CEILING FAN” |

Mr.Dharanesh O H |

| 4RA18MEO15 | Mr. KIRAN KUMAR H.L | ||

| 4RA18MEO19 | Mr. MANDEEP J | ||

| 4RA20ME405 | Mr. GURU PRASAD C.B | ||

Best Projects 2021-22

|

USN |

Student Name | Title |

Guide |

| 4RA17ME029 | Mr. LEKHAN B. C | Extraction of water from air | Mr. Anand H R |

| 4RA18ME025 | Mr. MOHAN H. R | ||

| 4RA18ME027 | Mr. NISHAN S | ||

| 4RA18MEO50 | Mr. YASHWANTH B | ||

| 4RA19ME407 | Mr. CHARAN G.S | Fabrication of Multipurpose agricultural vehicle by rocker bogie mechanism | Mr. Vinay L |

| 4RA19ME408 | Mr. NITHIN H. P | ||

| 4RA19ME423 | Mr. DILEEP S.B | ||

| 4RA19ME425 | Mr. MOHANSURYA C. S | ||

Best Projects 2020-21

| USN | Student Name | Title |

Guide |

| 4RA18ME400 | ABHILASH | Gesture control Robotic Arm | Mr.KK Pavan Kumar |

| 4RA18ME401 | ABHISHEK GOWDA B N | ||

| 4RA18ME407 | GOWTHAM B M | ||

| 4RA18ME408 | DUSHYANTH K S | ||

| 4RA17ME067 | V DARSHAN | Development of Ragi Mudde making Vessel | Mr.Rajeev KT |

| 4RA17ME069 | VISHWATH M S | ||

| 4RA17ME070 | YASHWANTH N. | ||

| 4RA17ME071 | YATHISH B D | ||

Best Projects 2019-2020

|

USN |

Student Name | Title |

Guide |

| 4RA15ME033 | HARSHA U A | Design and Fabrication of Onion De-topping and Sorting Machine | Mr.Muruli AS |

| 4RA15ME035 | HARSHITH C | ||

| 4RA15ME042 | LATHESH H P | ||

| 4RA15ME043 | LOKESH B K | ||

| 4RA15ME027 | CHARAN P M | Laser Guided Firing Gun and fire extinguisher use in unmanned vehicle | Mr.Muruli A S |

| 4RA15ME029 | DAKSHATH D | ||

| 4RA15ME048 | MANOHAR M V | ||

| 4RA15ME050 | MANU D C | ||

Sports Achievements

- RIT Men Cricket teams actively participated in Men Cricket Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Cricket Tournament 2022-23 organized by PESITM, Shivamoga.from 13th to 15th March 2023.

- RIT Men Volleyball teams actively participated in Men Volleyball Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Volleyball Tournament 2022-23 organized by AIT, Chikkamagaluru from 18th to 19th March 2023.

- RIT Men Football teams actively participated in Men Football Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Football Tournament 2022-23 organized by JNNCE, Shivamoga.from 05th to 06th Dec 2022.

- RIT M/W Athletic teams actively participated in M/W Athletic Meet organized under VTU events. Team took part in The VTU Inter Collegiate 23Rrd Athletic Meet 2021-22 organized by SJCIT, Chikkaballapura from 27th to 30th june 2022.

- RIT Men Swimming athlete actively participated in Men Swimming Championship organized under VTU events. Team took part in The VTU Inter Zone Men Swimming Championship 2021-22 organized by JYOTY IT BANGALURE from 15th Dec 2021.

- RIT Men Volleyball in the VTU Inter Collegiate Central Karnataka Zone Men Volleyball Tournament 2021-22 at SIT, TUMKUR from 31st NOV to 1st Dec 2021.

- RIT Men volleyball Team actively participated in Men volleyball Tournament organized under VTU events. Team took part in The VTU Inter Collegiate Central Karnataka Zone Men Volleyball Tournament 2021-22 organized by SIT, TUMKUR from 31st NOV to 1st Dec 2021

- RIT Men Cricket teams actively participated in Men Cricket Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Cricket Tournament 2020-21 organized by SIT, Tumakuru, from 06th to 14th Feb 2020.

- RIT Men Kho-Kho teams actively participated in Men Kho-Kho Tournament organized under VTU events. Team took part in The VTU Inter Collegiate Central Karnataka Zone Men Cricket Tournament 2020-21 organized by SIT, Tumakuru. from 27th to 28th Feb 2020.

- RIT Men Volleyball teams actively participated in Men Volleyball Tournament organized under VTU events. Team took part in The VTU Inter Collegiate Central Karnataka Zone Men Volleyball Tournament 2020-21 organized by SIT, Tumakuru, from 05th to 06th March 2020.

- RIT men Volley ball teams actively participated in Men Volleyball Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Volley ball Tournament 2019-20 organized by JNNCE Shimoga from 09th to 10th March 2019.

- RIT Men Mallakhamba and Gymnastic players actively participated in Men Mallakhamba and Gymnastic Tournament organized under VTU events. Team took part in VTU Inter Zone Men Mallakhamba and Gymnastic Tournament 2019-20 organized by VEMANA IT, Bangalore from 04th to 05h September 2019.

- RIT Men/Women Athletics teams actively participated in Inter Collegiate Men/Women VTU Athletic Meet organized under VTU events. Team took part in Inter Collegiate Men/Women VTU Athletic Meet 2019-20 organized by Shimoga from 22nd to 25th Oct 2019.

- RIT men Netball teams actively participated in Men Inter Collegiate Men Netball Tournament organized under VTU events. Team took part in VTU Rest of Bangalore Zone Inter Collegiate Men Netball Tournament 2019-20 organized by VDRIT, HALIYAL from 09th to 10th Nov 2019.

- RIT men gymnastic teams actively participated in Men gymnastic Tournament organized under VTU events. Team took part in The VTU Single Zone Inter Collegiate Gymnastic Tournament 2018-19 organized by BMSIT Bangalore from 23rd to 24th October 2018.

- RIT men Athletics actively participated in Men Zone Athletic Meet organized under VTU events. Team took part in The VTU Inter Zone Athletic Meet 2018-19 organized by SJCIT Chikkabalapura from 26th to 29th October 2018.

- RIT men Badminton teams actively participated in Men Badminton Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Men Badminton Tournament 2018-19 organized by MEC Hassan from 27th to 28th Aug 2018

- RIT men Kho-Kho teams actively participated in Men Kho-Kho Tournament organized under VTU events. Team took part in The VTU Inter Collegiate Central Karnataka Zone Men Kho-Kho Tournament 2018-19 organized by KIT College Tiptur from 01st to 02nd March 2018.

- RIT men kabaddi team actively participated in Men kabaddi Tournament organized under VTU events. Team took part in The VTU Central Karnataka Zone Inter Collegiate Men Kabaddi Tournament 2018-19 organized by BCE Hassan from 29th to 30th April 2018.

INDUSTRY INTERFACE

Mentoring Module Procedure

A maximum of twenty students are allotted to each one of the Counsellors. The counsellor should collect the details of each student in a prescribed format.

Counsellor should maintain a diary wherein he/she has to enter the details of any important communication happened with student such as not attaining minimum IA marks, long absence of student from classes due to some illness/accident etc. In case if the parent of any student accompanies the student in any of the sessions the version of the parent should be recorded in the diary along with the signatures of the student as well as the parent.

Counsellor should double check with the parent regarding the phone numbers that he/she has of student as well as parents. The counsellor should also inform the parent that any changes in address and contact details of student as well as parent should brought to immediate attention of the Counsellor.

Mentoring frequency The Mentor will schedule about three to four interactive sessions with students. The Counsellors should inform the students the day and time when he/she (counsellor) is free and ask students to meet up during that slot.

1st Mentoring Session will comprise the following points (Before IA test-1): ∙ Mentors will collect the List of Advanced, Average and Slow Learners from the class ∙ Discuss about the students Interests, Hobbies and their inclination towards curricular, co curricular and extracurricular

Discussion of previous semester’s Academic Discussion on importance of internal tests and attendance.

Enquire about the preparations for the 1st Internal

2nd Mentoring Meet (Before IA test-2):

Discuss about the 1st IA performance with respect to courses. If the student performance is unsatisfactory, then reasons for their low scoring are discussed and accordingly suggestions are given.

Students are encouraged to participate in co-curricular and extracurricular activities for various

3rd Mentoring Meet (Before IA test-3):

Discuss about the 2nd IA performance with respect to courses. If the student performance is unsatisfactory, then reasons for their low scoring are discussed and accordingly suggestions are given.

Students will be advised to attend the 3 IA compulsorily and to prepare action plan for the Semester End Exam preparation

4th Mentoring Meet (After IA test-3 Optional):

Non-compliance of any points raised in the above mentoring sessions will ∙ Students will be advised on the above

Note: The Internal Assessment performance and attendance status of each student will be communicated to the respective parents.

Maximum No. of Students per Mentor | 15 to 20 |

Frequency of Mentoring | 3 to 4 per Semester |

Prerequisite | Class Teachers prepares list of Advanced, Average and Slow Learners based on the previous Academic Performance |

Mentoring-I | Discussion and comments on: 1. Previous Performance 2. Hobbies & Co-curricular Activities 3. Teaching and Learning Process |

Mentoring-II | Discussion and comments on: 1. Review of previous counseling 2. IA-1 Performance 3. Teaching and Learning Process |

Mentoring-III | Discussion and comments on: 1. Review of previous counseling 2. IA-2 Performance 3. Teaching and Learning Process |

Mentoring IV (Optional) | Discussion and comments on: 1. Advice on Non-compliances |